| Search |

| Search |

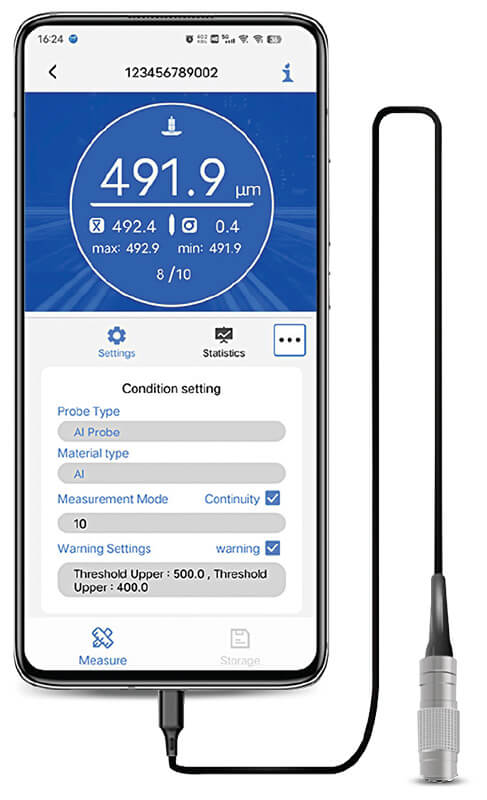

| Particulars | MCT 300 Mobile Generation Coating Thickness Guage | |

|---|---|---|

| Working principle | Magnetic induction | Eddy current |

| Probe type | F | N |

| Measuring range (μm) | 0 ~ 1500 | 0 ~ 1500 Chromium plating on copper 0-40 |

| Lower limit of resolution (μm) | 0.1 | 0.1 |

| Indication Value | ||

| Zero calibration (μm) (H refers to the actual thickness of the measured object) |

±(3%H + 1) | ±(3%H + 1.5) |

| Two point calibration (μm) (H refers to the actual thickness of the measured object) |

± [(1 ~ 3)% H +1] | ± [(1 ~ 3)% H +1.5] |

| Indication Value | ||

| Minimum radius of curvature (mm) | Convex 3 | Convex 3 |

| Diameter of minimum area (mm) | Ø7 | Ø7 |

| Critical thickness of matrix (mm) | 0.5 | 0.3 |

indicates influence)

indicates influence)

| Factors / Method | Magnetic Induction | Eddy Current |

|---|---|---|

| Magnetic properties of base metal |  |

|

| Electrical properties of base metal |  |

|

| Base metal thickness |  |

|

| Edge effect |  |

|

| Curvature |  |

|

| The deformation |  |

|

| Surface roughness |  |

|

| Magnetic field |  |

|

| Attached substance |  |

|

| Pressure of the probe |  |

|

| Direction of the probe |  |

|